Location:首页 > Products > Epoxy Fiber Glass > 正文

3240 Epoxy Fiber Glass Sheet

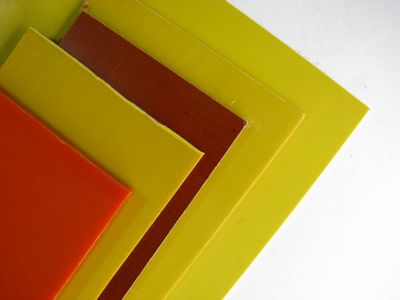

Name: 3240 EpoxyFiber Glass Sheet

Color include: yellow

ShapesInclude:Sheets

1. Define and purpose

Thislaminated product is formed through heat pressing after electric industryalkali glass cloth dips into the epoxy phenolic resin. It has high mechanic anddielectric performance, and applicable as insulation structural components forelectromechanical/electrical equipment, as well as used under dampenvironmental conditions and transformer oil .

2. Technical requirement for surface

Thesurface of laminated board should be flat and smooth, no bubble, no wrinkle, nodelamination or crackle, and properly free from other defects such as scrape, impress,

dirty spot and unevencolor, but a little color patches is allowed.。

3. Main performance index

A. Performance index

| Order | Item name | Unit | Test method | Index |

| 1 | Density | g/cm3 | GB/T5130 section 8.1 | (1.70-1.90) |

| 2 | Water absorption | mg | GB/T5130 section 8.2 | Refer to table 2 |

| 3 | Vertical layer direction bending strength | MPa | GB/T5130 section 5.1 | >= 340 |

| 4 | Vertical layer direction compression strength | MPa | GB/T5130 section 5.3 | >= (350) |

| 5 | Tensile strength | MPa | GB/T5130 section 5.7 | >= (300) |

| 6 | Compact strength (Simply strut-beam method) | KJ/m3 | GB/T5130 section 5.5.1 | >= 33 |

| 7 | Insulation resistance after water dipping | Ω | GB/T5130 section 6.3 | >= 5.0 × 108 |

| 8 | Mediate loss factor, 1MHz hour | ____ | GB/T5130 section 6.2 | <= 0.04 |

| 9 | Dielectric constant, 1MHz hour | ____ | GB/T5130 section 6.2 | <= 5.5 |

| 10 | Vertical layer direction electric strength at (90±2)℃ transformer oil | KV/mm | GB/T5130 section 6.1 | Refer to table 3 |

| 11 | Parallel layer direction striking voltage | kV | GB/T5130 section 6.1 | >= 35 |

B.Water absorption

| Average hickness mm | Water absorption mg | Average thickness mm | Water absorption mg | Average thickness mm | Water absorption mg |

| 0.4 | <= 17 | 2.0 | <= 20 | 10 | <= 34 |

| 0.5 | <= 17 | 2.5 | <= 21 | 12 | <= 38 |

| 0.6 | <= 17 | 3 | <= 22 | 14 | <= 41 |

| 0.8 | <= 18 | 4 | <= 23 | 16 | <= 46 |

| 1.0 | <= 18 | 5 | <= 25 | 20 | <= 52 |

| 1.2 | <= 18 | 6 | <= 27 | 25 | <= 61 |

| 1.6 | <= 19 | 8 | <= 31 | Single side processing to 22.5 | <= 73 |

C. Electric strength

| Average thickness mm | Average strength kV/mm | Average thickness mm | Electric strength kV/mm | Average thickness mm | Electric strength kV/mm |

| 0.4 | >= 16.9 | 1.0 | >= 14.2 | 2.2 | >= 11.4 |

| 0.5 | >= 16.1 | 1.2 | >= 13.7 | 2.4 | >= 11.1 |

| 0.6 | >= 15.6 | 1.4 | >= 13.2 | 2.5 | >= 10.9 |

| 0.7 | >= 15.2 | 1.6 | >= 12.7 | 2.6 | >= 10.8 |

| 0.8 | >= 14.8 | 1.8 | >= 12.2 | 2.8 | >= 10.5 |

| 0.9 | >= 14.5 | 2.0 | >= 11.8 | 3.0 | >= 10.2 |

the above product is in conformity with UL with yellowcard certificate No. E117719.

Application

1. Chemicalmachinery parts, general machinery parts

2. Gears,generators, pads, bases, baffles, generator, transformer, fixture inverter,motor and electric insulation component.

3. Distribution box, fixture board,the mould plate, high and low voltage distribution box, packing machineinsulation parts.

4. Mold making, PCB,ICT fixture,molding machine, drilling machine, mesa grinding pads etc.

IV. Size:

| Epoxy fiber glass sheet | |

| thickness(mm) | Width/Length(mm) |

| 0.5-2mm | 1020mm x 2020mm |

| 3--70mm | 1020mm x 2020mm |

| 75-180mm | 1020mm x 2020mm |